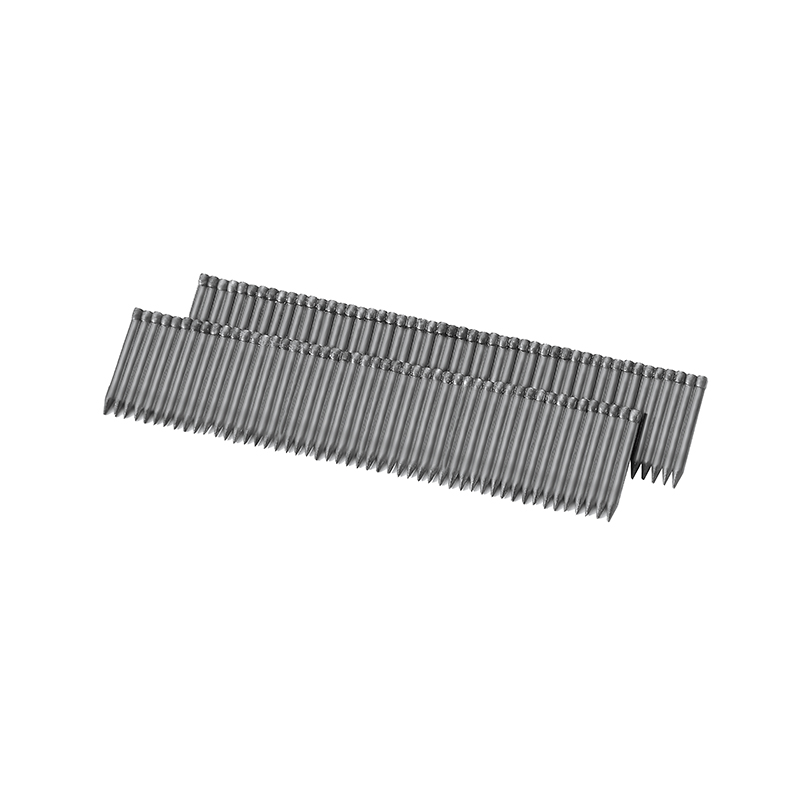

Annular stainless steel nails are a specialized type of fastener designed for specific applications where durability, corrosion resistance, and strength are paramount. These nails, characterized by their annular (ring-shaped) design, offer unique advantages that make them suitable for a variety of industrial and construction tasks.

Stainless steel is renowned for its corrosion resistance, strength, and durability. Annular stainless steel nails inherit these qualities, making them suitable for use in environments where exposure to moisture, chemicals, or harsh weather conditions is likely. Stainless steel nails do not rust easily and maintain their integrity over time, ensuring that the fastened materials remain securely attached.

The annular design of these nails provides a unique advantage. The ring-shaped head of the nail offers a larger surface area for contact, which helps distribute the force more evenly when the nail is driven into the material. This design reduces the risk of splitting or damaging the material being fastened, making it particularly useful for delicate or thin materials.

They are often employed in roofing applications, where their corrosion resistance is crucial for longevity. These nails can secure roofing materials, such as shingles or metal sheets, ensuring that they remain in place despite exposure to the elements. The annular design also helps prevent damage to the roofing materials during installation.

Annular stainless steel nails are also used in furniture making, especially for attaching delicate or thin pieces of wood. The larger head of the nail reduces the risk of splitting the wood, making it a preferred choice for craftsmen who require precision and reliability. The stainless steel material ensures that the nails do not rust or corrode, maintaining the structural integrity of the furniture over time.

Annular stainless steel nails are used for securing components that require a high degree of precision and durability. These nails can be used to attach panels, brackets, and other parts where a secure and long-lasting fastening is necessary. The corrosion resistance of stainless steel ensures that the nails remain effective even in environments exposed to oil, grease, and other chemicals.

The corrosion-resistant nature of stainless steel makes annular stainless steel nails ideal for marine and outdoor applications. They can be used to fasten components on boats, docks, and other marine structures. The nails' ability to withstand saltwater and harsh weather conditions ensures that they remain secure and functional for extended periods.

The primary advantage of annular stainless steel nails is their durability. Stainless steel is resistant to corrosion, rust, and wear, ensuring that the nails maintain their strength and integrity over time. This longevity reduces the need for frequent replacements and maintenance, making them a cost-effective solution for long-term projects.

Annular stainless steel nails are designed to provide a strong and reliable fastening. The annular head distributes the force more evenly, reducing the risk of material damage during installation. This design also ensures that the nails remain securely in place under various conditions, providing a dependable fastening solution.

The polished finish of stainless steel gives the nails a sleek and modern look, making them suitable for applications where appearance is important. This aesthetic quality, combined with their practical advantages, makes them a popular choice for both functional and decorative purposes.

Annular stainless steel nails are a versatile and reliable fastening solution suitable for a wide range of applications. Their unique design and durable material make them ideal for construction, furniture making, automotive, marine, and outdoor use. The strength, corrosion resistance, and aesthetic appeal of these nails ensure that they provide long-lasting and secure fastening.

English

English русский

русский 中文简体

中文简体 عربى

عربى

Quick Links

Quick Links