N/100 Staples: Common Applications and Best Uses

N/100 Staples are widely used across both home and professional environments, offering a reliable way to fasten materials neatly and consistently. In offices, they are often applied for binding stacks of documents, securing files, or attaching labels. For packaging, they help close cardboard boxes and strengthen paperboard edges, making them suitable for shipping or storage.

Beyond offices and packaging, N/100 Staples are also common in light manufacturing and craft projects. They are effective for attaching thin materials such as fabric, lightweight plastics, or insulation sheets. Compared to clips or adhesives, staples provide a stronger hold and allow for quick application without the need for drying time. This versatility explains why they remain a standard fastening option in both small-scale and large-scale use cases.

N/100 Staples: Specification Differences and Material Selection

Choosing the right staple specification is an important step in achieving reliable fastening. N/100 Staples generally come in 16 Gauge, which provides a balance of strength and ease of penetration. The gauge refers to wire thickness, while the length of the legs determines how deep the staple can secure into the material. For thin paper or fabric, shorter legs are sufficient, while thicker cardboard or layered materials may require longer legs for a secure grip.

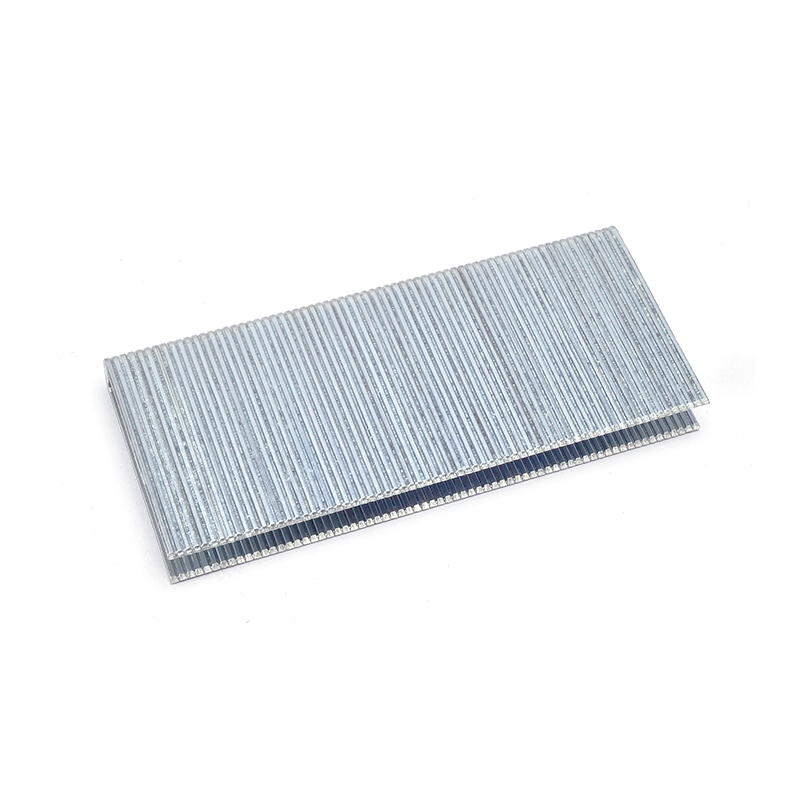

Material selection also makes a difference in performance. Galvanized staples are coated to resist corrosion, making them suitable for storage in slightly humid environments. Stainless steel versions offer additional durability and are often chosen for outdoor or long-term applications. For indoor use, standard steel staples typically provide the necessary strength at an economical cost.

Another detail to note is the coating finish. Smooth staples are easier to drive into material, while resin-coated options add holding strength once the staple sets. Understanding these differences helps users select the right product for each job, reducing the risk of loosening or material damage.

N/100 Staples: Best Practices for Tool Use and Maintenance

The efficiency of N/100 Staples depends not only on the staples themselves but also on how they are used with tools such as staplers or pneumatic nail guns. Matching the correct staple size with the compatible tool is essential. Using staples that are too long or too thick for the stapler may cause jams, while undersized staples may fail to fasten securely.

When loading staples into the tool, ensure that they are aligned properly to avoid misfiring. Applying steady pressure and keeping the tool at a consistent angle helps achieve uniform fastening. For heavy-duty applications like packaging or carpentry, adjusting the driving power can prevent staples from being overdriven or underdriven.

Maintenance also plays an important role in staple performance. Tools should be kept clean and free from dust or debris, while unused staples should be stored in a dry area to prevent rust.

Recommendation

For projects that require dependable fastening, selecting the right type of staple is essential. Among available options, the 16 Gauge N/55/100 Series Staples from Chaoyue Company provide a practical choice for both household and professional applications. They are designed to meet a range of fastening needs while maintaining consistent quality.

Anyone interested in exploring detailed specifications, reviewing available sizes, or learning more about purchasing options is encouraged to reach out to Chaoyue Company directly or visit the official website for further information. Choosing the right N/100 Staples can make everyday tasks and professional projects more efficient and reliable.

English

English русский

русский 中文简体

中文简体 عربى

عربى

Quick Links

Quick Links