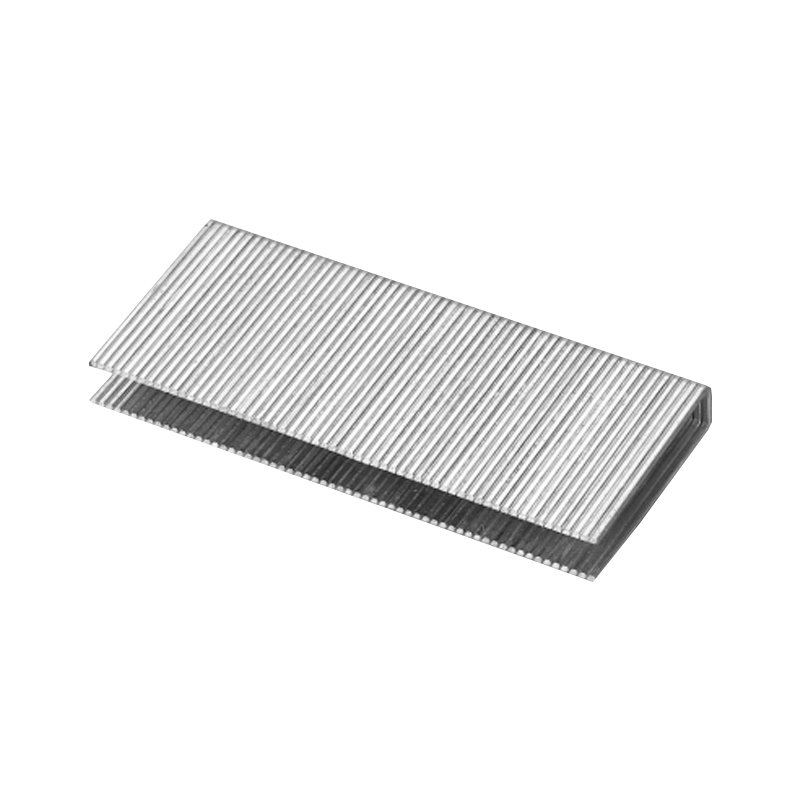

Heavy Wire Staples are widely used in construction, flooring, and packaging because they provide firm fastening for demanding tasks. While they look simple, many people still ask questions about how to choose the right type, what tools are needed, and how to ensure long-lasting results.

Heavy Wire Staples: What Materials Can They Fasten?

A frequent question is whether heavy wire staples are suitable only for wood or if they can be applied to other materials. In reality, these staples are designed for multiple uses.

Wood Applications: Ideal for hardwood flooring, plywood panels, and furniture assembly.

Packaging and Shipping: Useful for securing heavy cartons or crates during transport.

Plastics and Composite Materials: Can be applied where screws or nails may cause cracking.

Light Metals or Mesh: In some cases, heavy wire staples can secure thin sheets or fencing.

This versatility makes them valuable in both professional industries and household projects.

Heavy Wire Staples: How to Choose the Right Size?

Another common concern is how to pick the correct length and thickness. Choosing the right size is essential to ensure strong fastening without damaging materials.

Material Thickness: For thicker wood panels or flooring, longer staple legs provide better grip. For thinner surfaces, shorter legs prevent splitting.

Width and Gauge: Wider crowns distribute pressure, while a heavier gauge provides strength for dense materials.

Application Type: For flooring, staples need to penetrate deep enough to hold panels firmly. For light packaging, smaller sizes may be sufficient.

Incorrect choices cause problems such as loose fastening or unnecessary wear on the stapler tool. By matching staple size to the task, users can improve overall reliability.

Heavy Wire Staples: Which Tools Work Best?

Many users also wonder if heavy wire staples require special tools. While they can work with a range of staplers, performance depends on the compatibility of the tool and staple.

Pneumatic Staplers: Provide strong force and are preferred for flooring and construction tasks.

Electric Staplers: Convenient for medium-duty use, balancing power and ease of handling.

Manual Staplers: Suitable for smaller jobs, though not always effective for continuous heavy fastening.

Selecting a compatible stapler reduces the risk of jams, improves efficiency, and extends tool lifespan.

Heavy Wire Staples: How to Ensure Safety and Longevity?

Durability is another concern often raised. Users ask whether staples will rust, loosen, or compromise the quality of the project.

Material and Coating: Galvanized or stainless staples resist rust, making them appropriate for outdoor or humid conditions.

Storage: Keeping staples in a dry environment helps preserve quality.

Application Safety: Wearing protective gear and ensuring correct placement reduces accidents and ensures consistent fastening.

These practices extend the usefulness of staples while maintaining safety during operation.

Recommendation

For projects that require dependable fastening solutions, the 15 Gauge 98 Series Flooring Staples from Chaoyue Company are a solid option. They are designed to handle demanding applications such as flooring and structural fastening, offering both strength and durability.

Anyone interested in detailed product information or specifications can reach out to Chaoyue Company directly or visit the official website for more details.

Heavy Wire Staples remain an essential fastening choice, and with the right selection and usage, they can provide reliable performance across a wide range of tasks.

English

English русский

русский 中文简体

中文简体 عربى

عربى

Quick Links

Quick Links