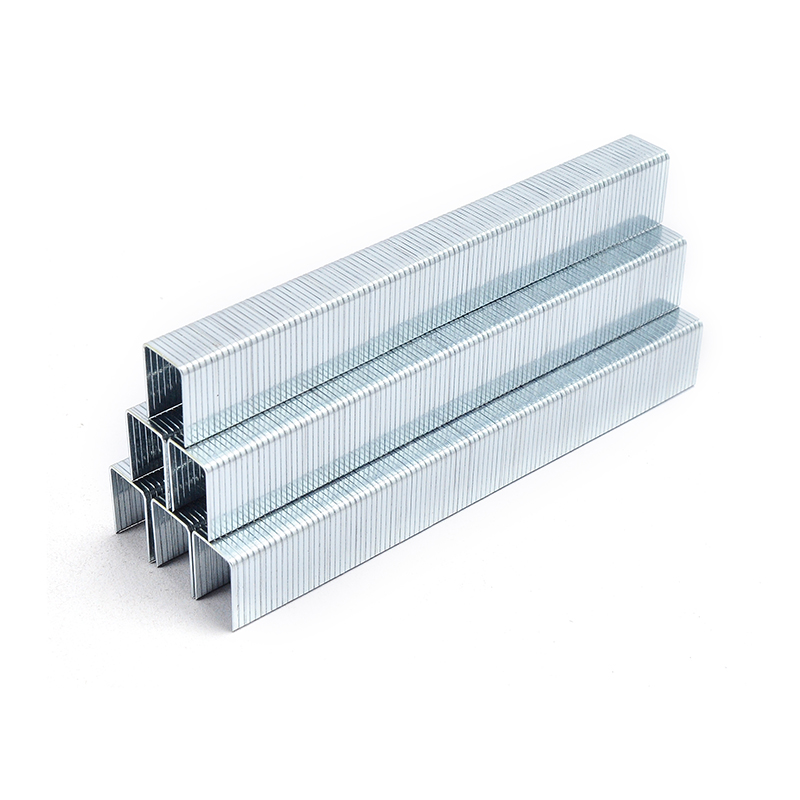

Medium Wire Staples are widely recognized for their ability to balance strength and flexibility, making them an essential tool for both household tasks and professional industries. Their moderate thickness allows them to hold materials securely without causing unnecessary damage, offering a practical option for a variety of fastening needs.

Medium Wire Staples: Everyday and Professional Applications

Medium wire staples are frequently used in household projects where durability is important but excessive force is unnecessary. For example, they are often chosen when attaching fabric to furniture frames, securing decorative panels, or fixing the backboards of cabinets. Their holding power is sufficient to keep materials in place while maintaining a clean appearance.

In professional settings, these staples play an equally valuable role. Packaging companies rely on them to close boxes securely, while retail environments use them for building display fixtures or lightweight wooden structures. Their ability to adapt to both delicate and moderately heavy-duty tasks has made them a reliable option across different industries. By bridging the gap between light wire and heavy wire staples, they remain versatile for varied applications.

Medium Wire Staples: Choosing the Right Size and Type

When selecting staples, size and type are two important considerations. Medium wire staples, often available in specifications such as 20 Gauge 10J Series, provide a well-rounded solution for many fastening jobs.

For soft or thin materials, shorter legs prevent damage and provide just enough grip. For harder or thicker materials, longer legs offer deeper penetration and better hold. It is also important to consider the working environment.

When users take factors like wire gauge, leg length, and coating into account, it becomes easier to choose staples that match the needs of each project. The right choice reduces the risk of weak fastening or surface damage, while still providing dependable grip.

Medium Wire Staples: Installation Tips for Better Results

The effectiveness of medium wire staples is not only determined by their design but also by how they are applied. Using a compatible staple gun is the step to smooth operation. Selecting a tool designed for the staple series in use helps prevent jams and ensures consistent penetration.

During installation, even pressure and the correct angle can make a noticeable difference. Applying staples too forcefully may cause them to bend or split the material, while insufficient pressure may result in loose fastening. Keeping the surface flat and stable also improves results.

Common challenges, such as bent staples, partial penetration, or over-driving into the material, can often be addressed through proper tool maintenance and technique adjustment. With attention to these details, users can achieve clean, reliable fastening results that support both functionality and appearance.

Recommendation

For those seeking a dependable fastening solution, Chaoyue Company’s 20 Gauge 10J Series Staples represent a practical choice. These staples are designed to combine secure holding power with ease of use, making them suitable for a wide range of tasks. Anyone interested in learning more about specifications, available models, or tailored guidance is encouraged to contact Chaoyue Company directly or visit the official website for detailed information.

Medium Wire Staples remain an important option for projects that require both strength and adaptability, offering dependable fastening solutions for tasks ranging from home improvements to professional use.

English

English русский

русский 中文简体

中文简体 عربى

عربى

Quick Links

Quick Links